PROJECT Elegance

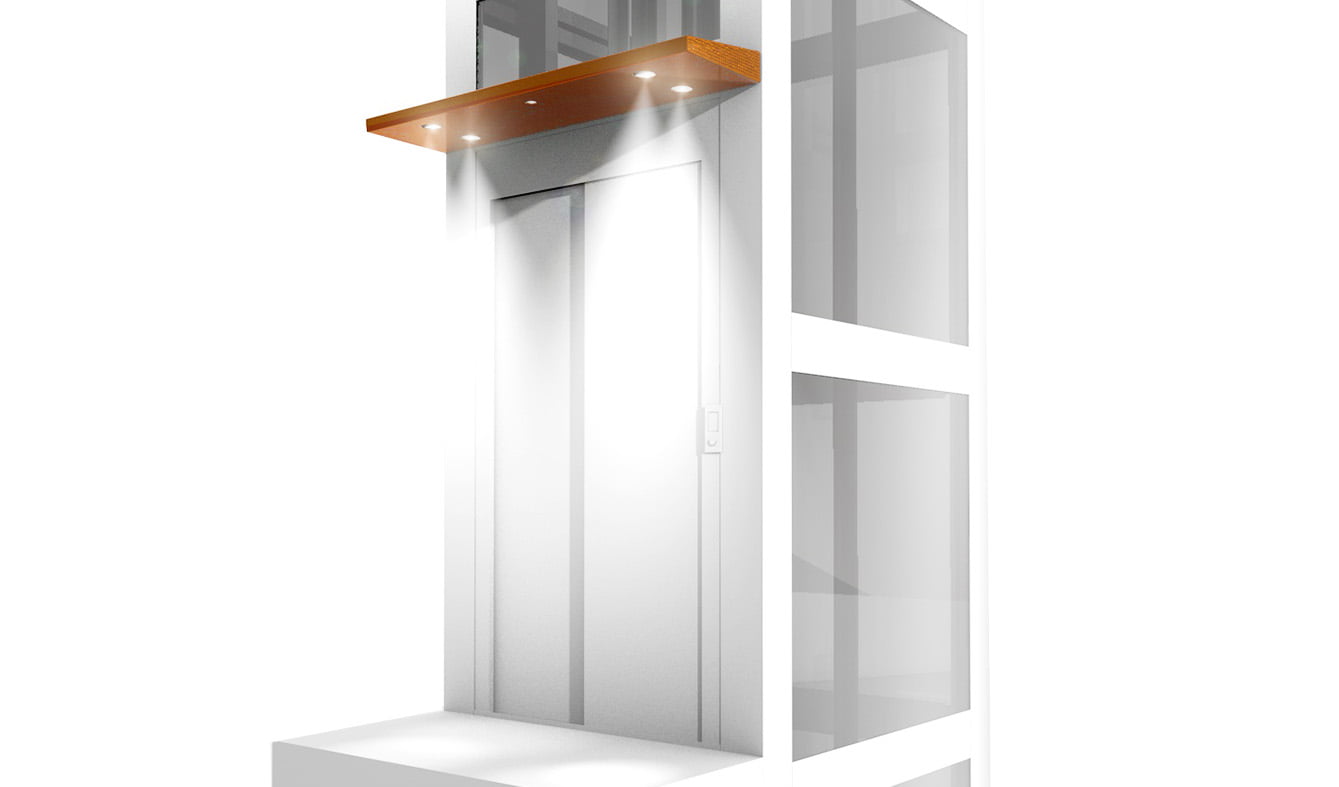

Project Elegance is an elevator shaft made of prepainted steel, covered with glass, and featuring large glazed mirrors. This product is developed using 3D parametric systems that facilitate automated production. The structure is designed for installation of electrically or hydraulically operated systems and is equipped with adjustable components to simplify installation.

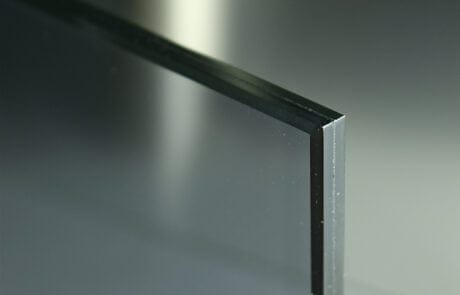

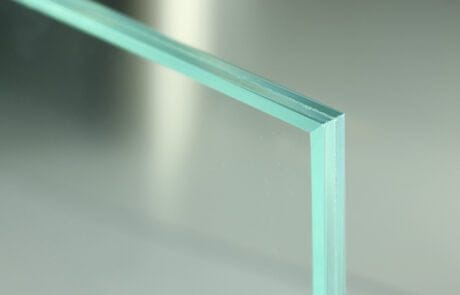

Wide mirrored paneling and the total absence of visible bolting give the structure a very elegant and regular appearance. Glass infills are installed from the outside and are separated by a low height profile that maximizes the amount of visible glass area. Once installed, the infills are placed flush with the exterior surfaces, promoting rainwater and dust runoff, ensuring greater durability and cleanliness of the building.

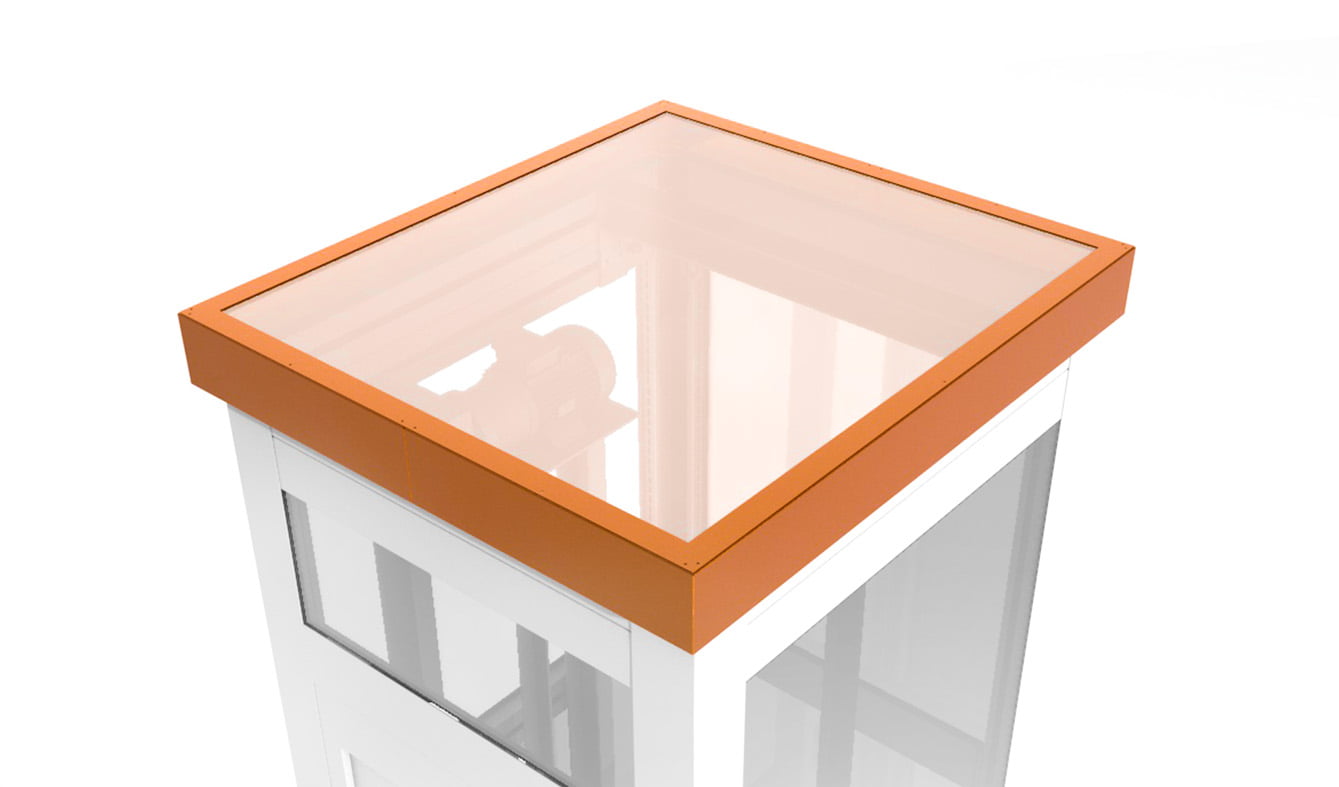

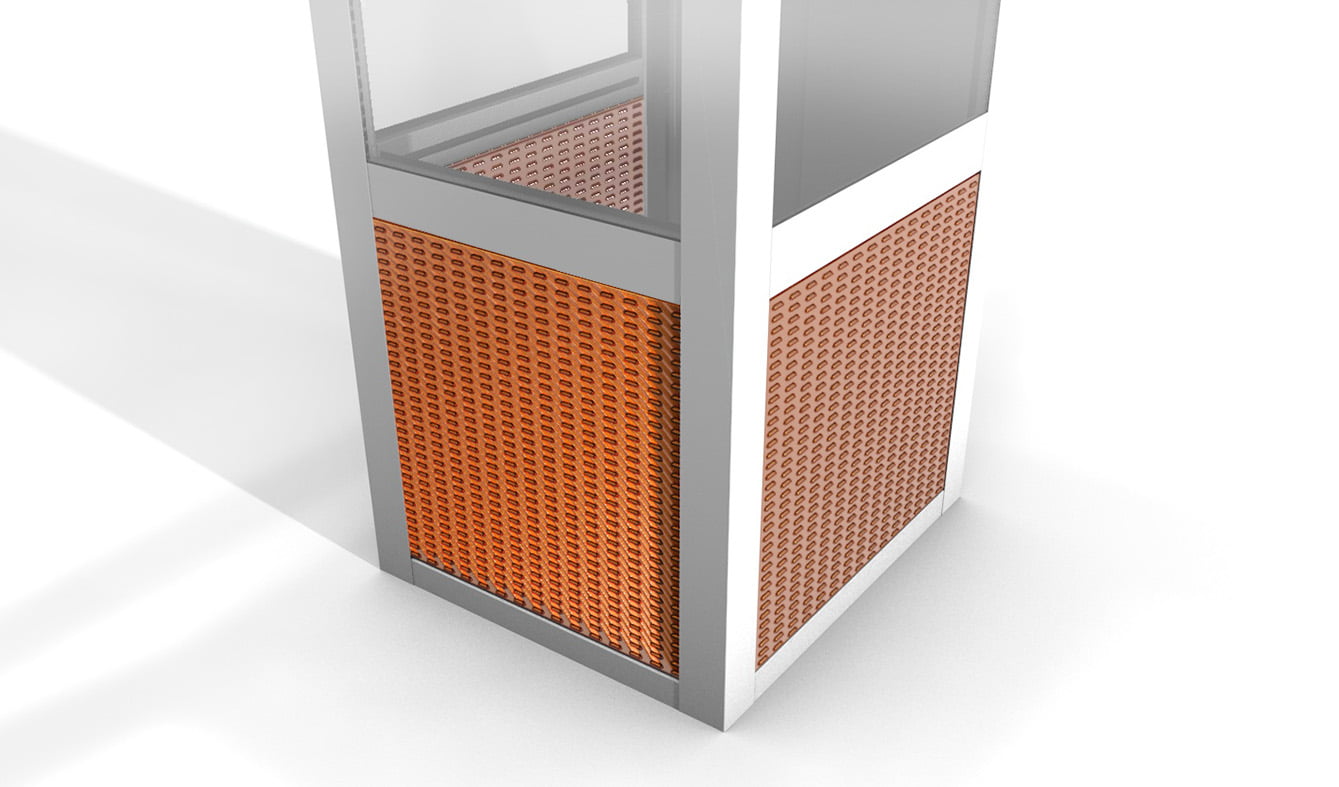

The facility includes a variety of accessories and options, such as stainless steel siding, glass roofs, canopies and ventilation systems. Anti-corrosive treatments and painting are carried out through industrial processes that ensure extreme durability and high aesthetic quality. All components and assembly systems are developed and tested on a large number of installations, ensuring excellent reliability and performance.

Project Elegance is a large glazed area structure with reduced-section interposing profiles designed to maximize the amount of glazed area visible from the outside. This design makes it particularly elegant and suitable for refined environments, where aesthetics plays an important role in enhancing the elevator as a distinctive element. Regular shapes facilitate integration into a variety of architectural contexts. Finishing options with special paints and stainless steel cladding allow for better integration , fitting perfectly with different styles and aesthetic preferences. The combination of high-quality materials and sophisticated design makes Project Elegance an ideal choice for those who want an elevator shaft that is not only functional, but also a distinctive element of architectural design.

TECHNICAL DETAILS

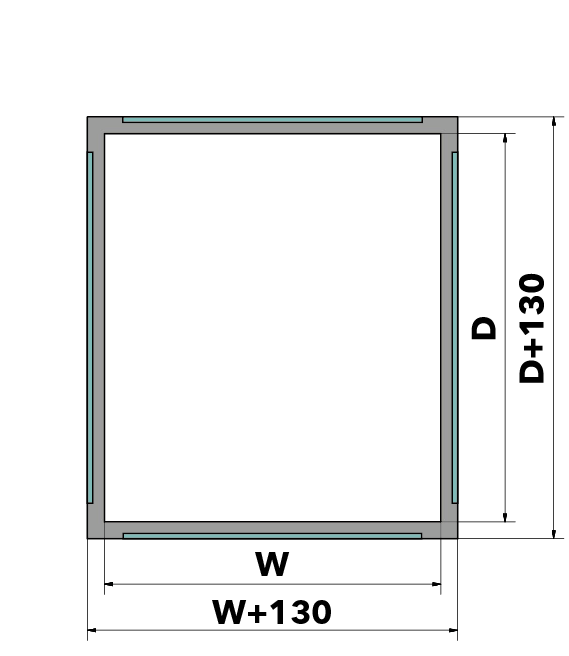

Compartment for elevator systems with capacities from 400 to 1200 kg designed with assistance in 3D environment, ensuring accuracy and adaptability. The structure, made of commercial sections and sheet steel, is processed by laser cutting, punching and CNC bending machines. Installation is by bolting and stabilization fasteners to the building, with a standard configuration involving connections at the base, landings, and header. Special configurations are possible with free header to be evaluated specifically.

For outdoor versions, there is an antioxidant treatment performed by cataphoresis, while for indoor versions, the surface finish is done by powder coating. During installation, the compartment offers considerable adaptability, including the possibility of repositioning all horizontal profiles every 40 mm and adjustment of +/- 15 mm. Rail support brackets are connected on profiles with continuous adjustment provision, allowing for adaptation and plumbing during installation.

INTERACTIVE 3D MODEL

- 1

Heavy-duty beam with or without eyebolts. Repositionable during installation.

- 2

Cable passage inside the vertical profiles, inspectable with removal of protective cover.

- 3

Horizontal profile with continuous arrangement for fixing rail support brackets, repositionable during installation.

- 4

Vertical profiles with hidden joints.

- 5

Base frame with plug-in joints. Can be installed by fixing with dowels or masonry.

- 6

Roof for indoor or outdoor installation.

- 7

Stabilization frame with cross, also made in two parts for easy shipping and installation.

- 8

Glass infill, which can be installed from the inside and is also interchangeable during installation.

- 9

Generic horizontal profile, repositionable during installation.

- 10

Horizontal profile with provision for fixing floor doors, repositionable and adjustable during installation.

FINISHES AND ACCESSORIES

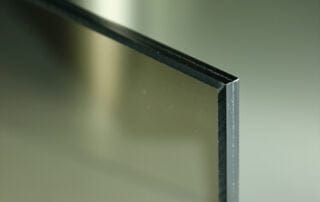

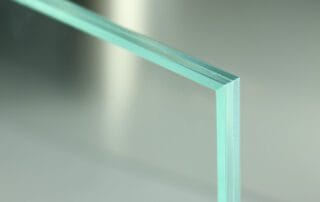

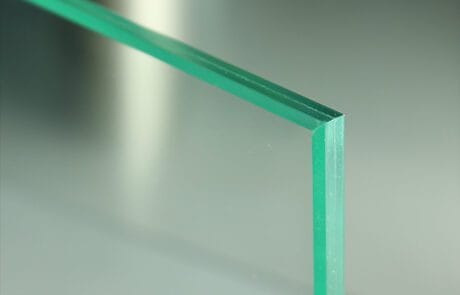

Glasses

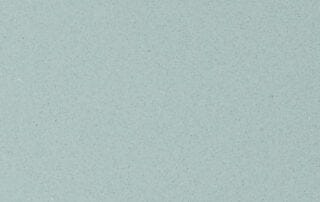

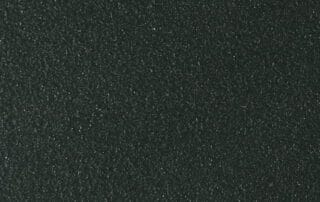

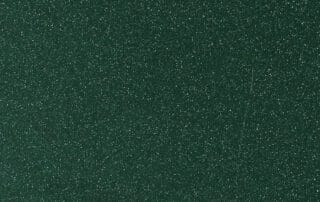

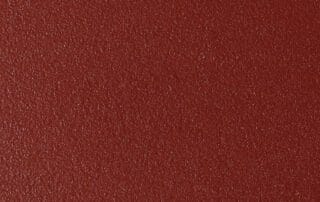

Coating and painting

Accessories

SUPPLY DETAILS

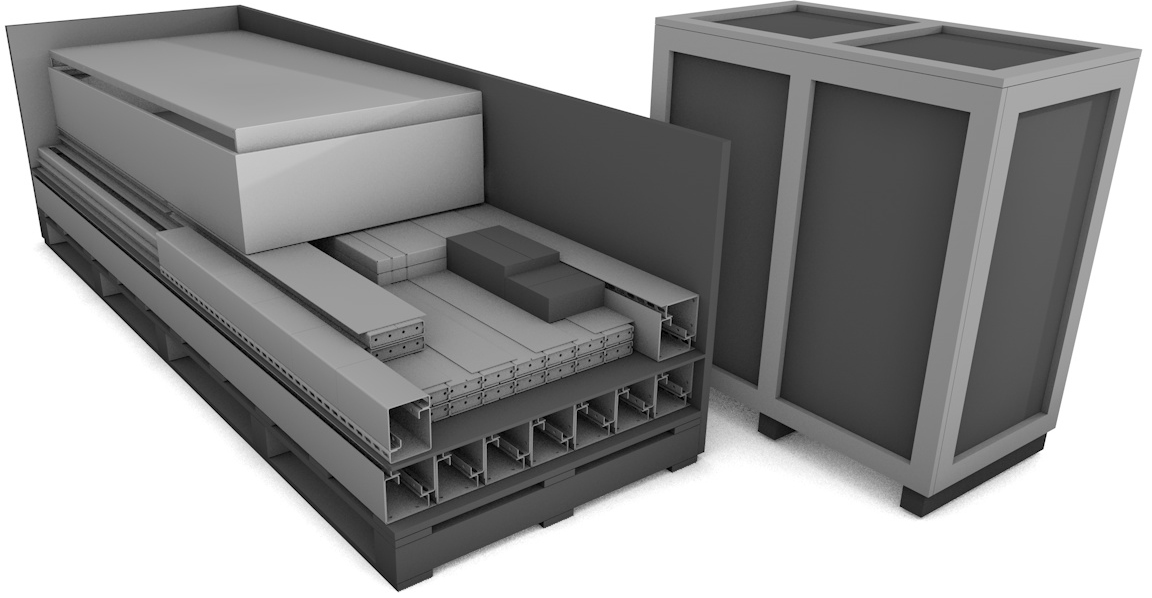

The structure is supplied in a custom-made kit ready for installation on site by bolting and connecting to the host building. It is shipped in a sturdy wooden crate, suitable for shipping, and includes the following items:

- Frame components: All structural and connecting elements, complete with paint.

- Accessories: All required accessories, made to measure.

- Infill: Glazed or blind infill.

- Assembly kit: Galvanized steel screws and bolts, and accessories needed for complete assembly.

- Technical drawings: Detailed technical drawings.

- Manuals: Detailed documentation for installation and use.

- Calculation report: Dedicated calculation report in accordance with Eurocode 3 (UNI EN 1993-1-1:2005).

- CE Marking: Marking according to UNI EN 1090-2:2018.

The structure is available with or without buffering. Alternatively, the technical specifications and dimensions of the planned infills are provided. Excluded from supply are dowels or chemical anchor for connection to the building, and silicones.