PROJECT CLASSIC

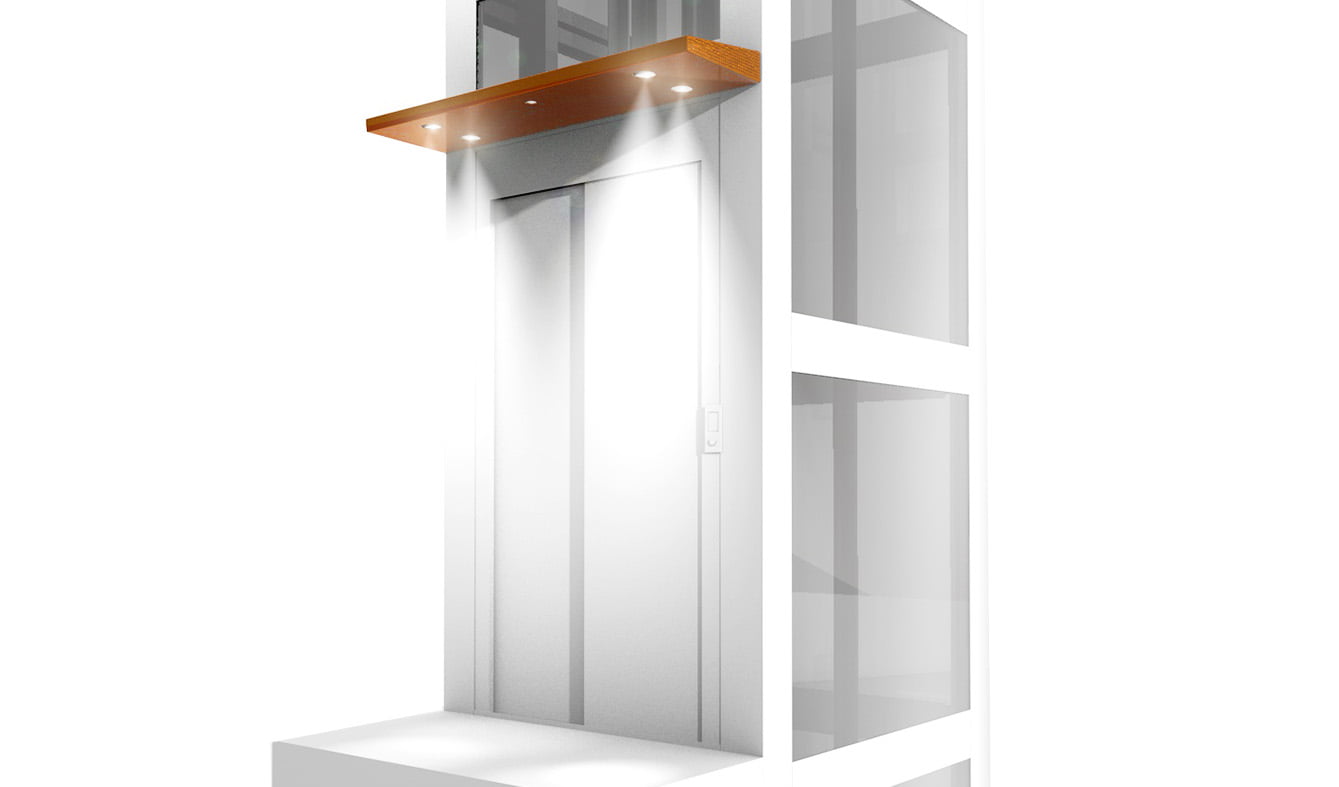

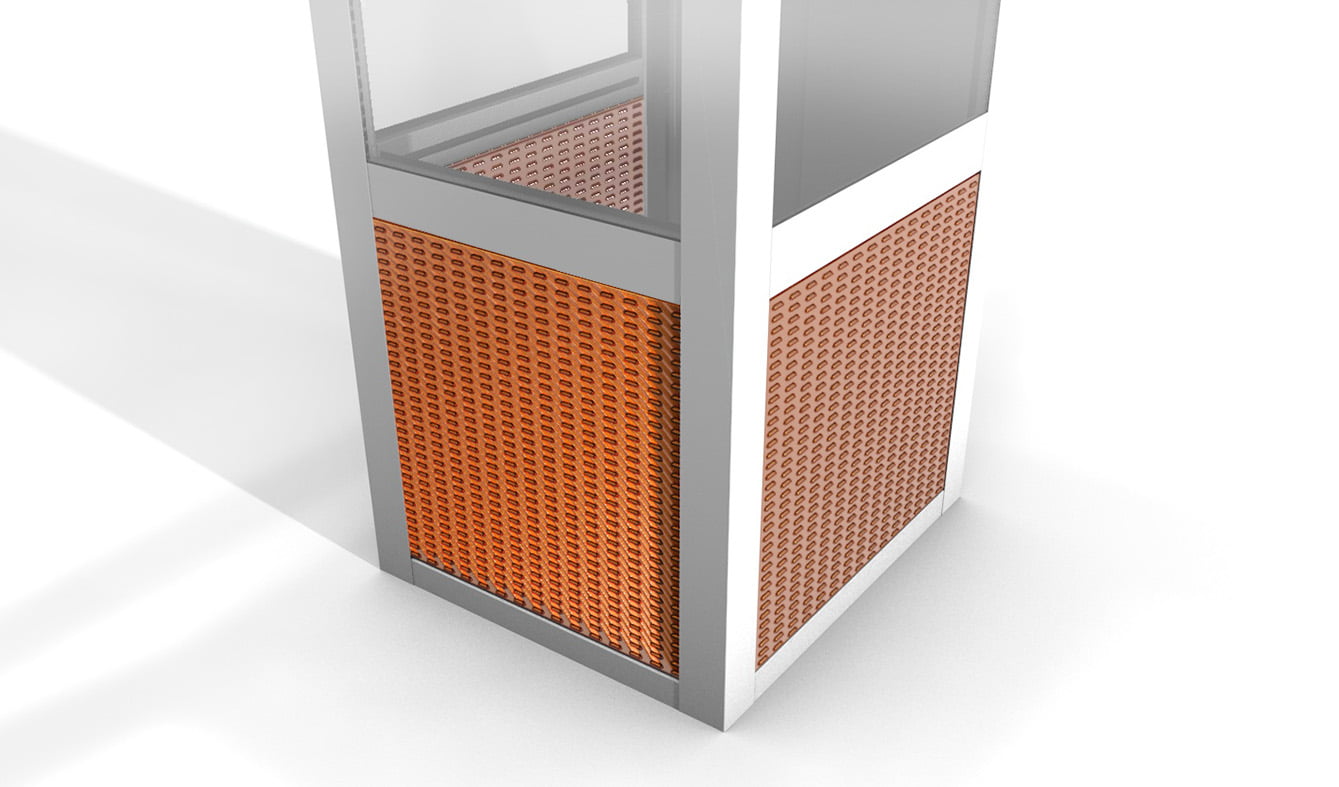

Project Classic is a prepainted steel elevator shaft characterized by extreme versatility and a high degree of modularity, developed using 3D parametric systems that facilitate automated production. The structure is designed for installation of electrically or hydraulically operated systems and is equipped with adjustable components to simplify installation. Its great versatility allows it to be used for systems with capacities from 400 to 2000 kg, even with challenging heights or installation conditions. The total absence of visible bolting gives the structure a very elegant and regular appearance. The infill panels are installed from the inside and can be glass or opaque. Once installed, they are placed flush with exterior surfaces, promoting rainwater and dust runoff, and ensuring greater durability and cleanliness of the building.

The facility includes a variety of accessories and options, such as stainless steel siding, glass roofs, canopies, ventilation systems, and landing walkways. Anti-corrosive treatments and painting are carried out through industrial processes that ensure extreme durability and high aesthetic quality. All components and assembly systems are developed and tested on a large number of installations. The delivery includes a dedicated calculation report according to Eurocode 3 (UNI EN 1993-1-1:2005) and CE marking according to UNI EN 1090-2:2018.

Continuous development and a large number of installations over about 25 years guarantee technical, aesthetic and functional performance. The linear design and wide range of finishes allow the structure to easily fit the image and identity of any installation context.

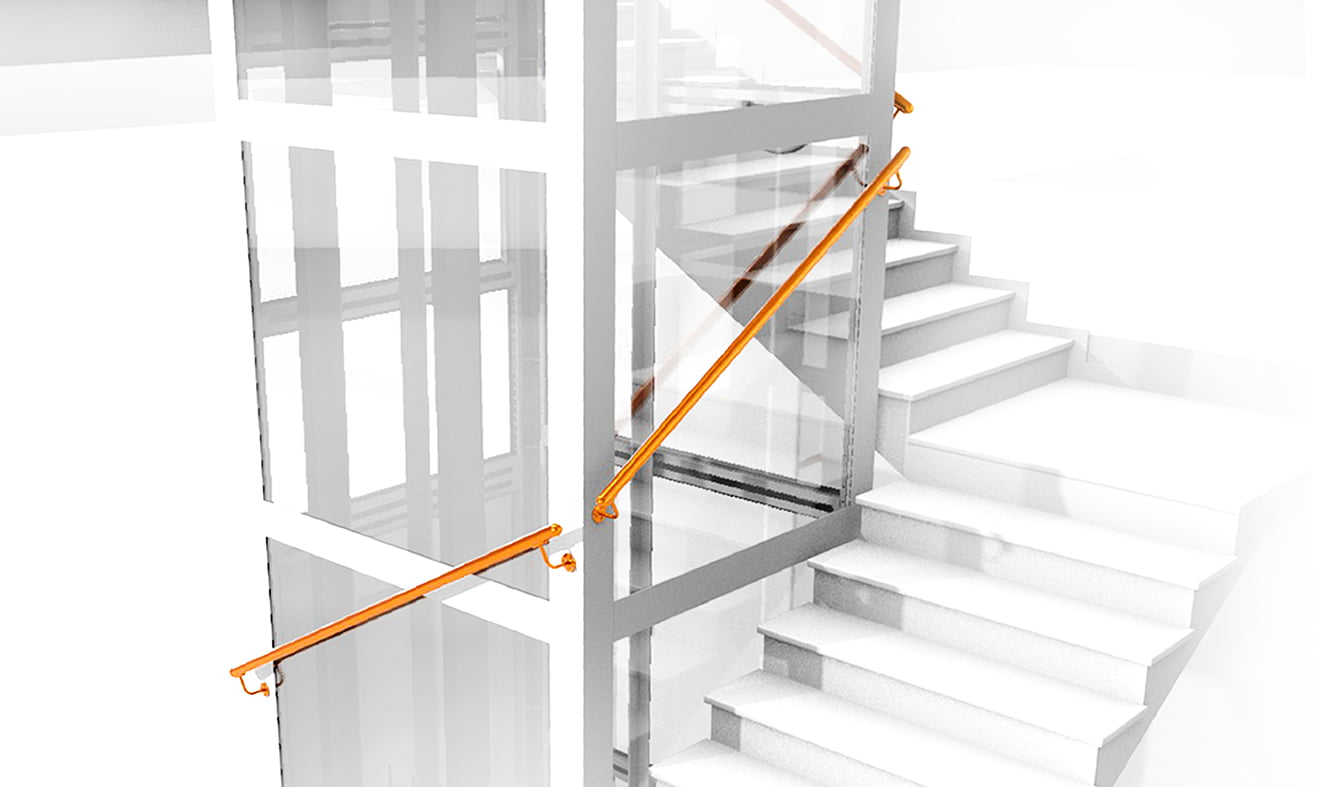

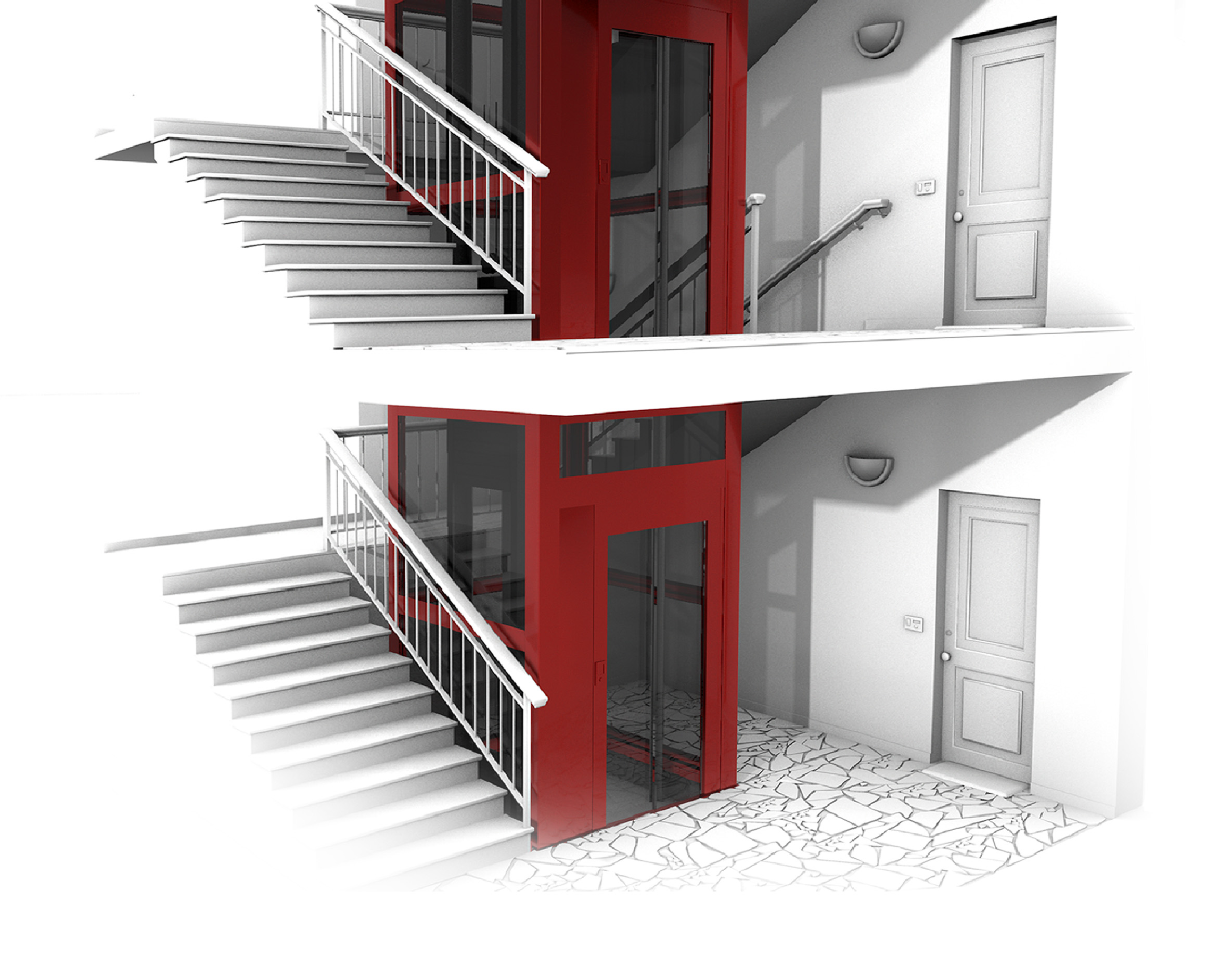

INSTALLATION INSIDE THE STAIRWELL

It is possible to place the lifting platform compartment inside the stairwell. The small thickness of the compartment ensures a high possibility of insertion. However, if the minimum required spaces are not available, the necessary area can be obtained by reducing the width of the stairs to the minimum allowed. In this case, the lift platform compartment can be used as protection by installing a handrail profile directly on it (available as an option).

This intervention ensures the construction of a regulation-compliant elevating platform, making it accessible and functional for people with mobility impairments.

Installation close to a wall

It is possible to place the lifting platform compartment close to a wall by arranging accesses through openings on the wall. It is also possible to add landings on opposite or side-by-side sides, allowing direct access to the outside or in other directions, adapting to the functional and architectural characteristics of the building.

This solution generally involves placing the plant and facilities outside the building, thus avoiding the occupation of interior spaces. It allows a high degree of adaptation to the layout characteristics of the building, making the elevating platforms highly usable even for people with mobility difficulties and ensuring easy and safe use.

Installation with Open Landing Walkways

In buildings that do not have sufficiently large landing areas, elevating platform compartments with built-in balconies can be provided. This solution not only improves the usability of lift platforms, but also contributes to making buildings more inclusive and accessible, especially for people with mobility impairments, while ensuring easy and safe use for all. This option, adapted to current accessibility and safety regulations, also allows access to any tax benefits provided for the removal of architectural barriers.

Installation with integrated closed landing gangways

In buildings that do not have sufficiently large landing areas, elevating platform compartments with integrated enclosed landing walkways can be provided. These walkways improve usability and provide safe and comfortable access in all weather conditions. They can also be equipped with opening windows, thus allowing adequate natural light and ventilation to the connected rooms. This solution, which complies with current accessibility and safety regulations, improves the usability of elevators and helps make buildings more inclusive and accessible, especially for people with mobility impairments. In addition, it can allow access to tax benefits provided for the removal of architectural barriers.

TECHNICAL DETAILS

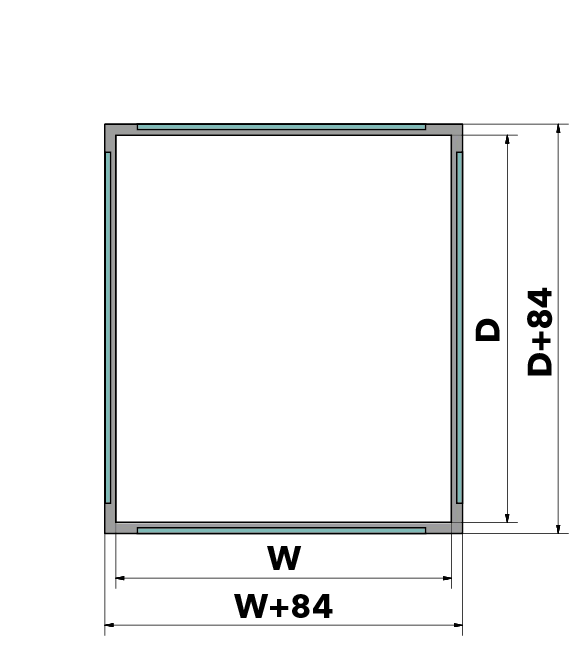

The compartment for lift systems with capacities from 400 to 2000 kg is designed with assistance in a 3D environment, ensuring accuracy and adaptability. The structure, made of commercial sections and sheet steel, is processed by laser cutting, punching and CNC bending machines. Installation is by bolting and stabilization fasteners to the building, with a standard configuration involving connections at the base, at the landings in at least two places, and at the head in at least two places. Special configurations with free header are possible.

For outdoor versions, there is an antioxidant treatment performed by cataphoresis, while for indoor versions, the surface finish is done by powder coating. During installation, the compartment offers considerable adaptability, including the possibility of repositioning all horizontal profiles every 40 mm and adjustment of +/- 15 mm. Rail support brackets are connected on profiles with continuous adjustment provision, allowing for adaptation and plumbing during installation.

INTERACTIVE 3D MODEL

- 1

Heavy-duty beam with or without eyebolts. Repositionable during installation.

- 2

Horizontal profile for supporting heavy loads. Variable dimensions depending on loads.

- 3

Internal cable routing to vertical profiles. Inspectable with removal of protective cover.

- 4

Horizontal profile with continuous arrangement for fixing rail support brackets. Repositionable during installation.

- 5

Vertical profiles with concealed joints. Variable sizes depending on structural characteristics.

- 6

Base frame with plug-in joints. Installable by fixing with dowels or masonry.

- 7

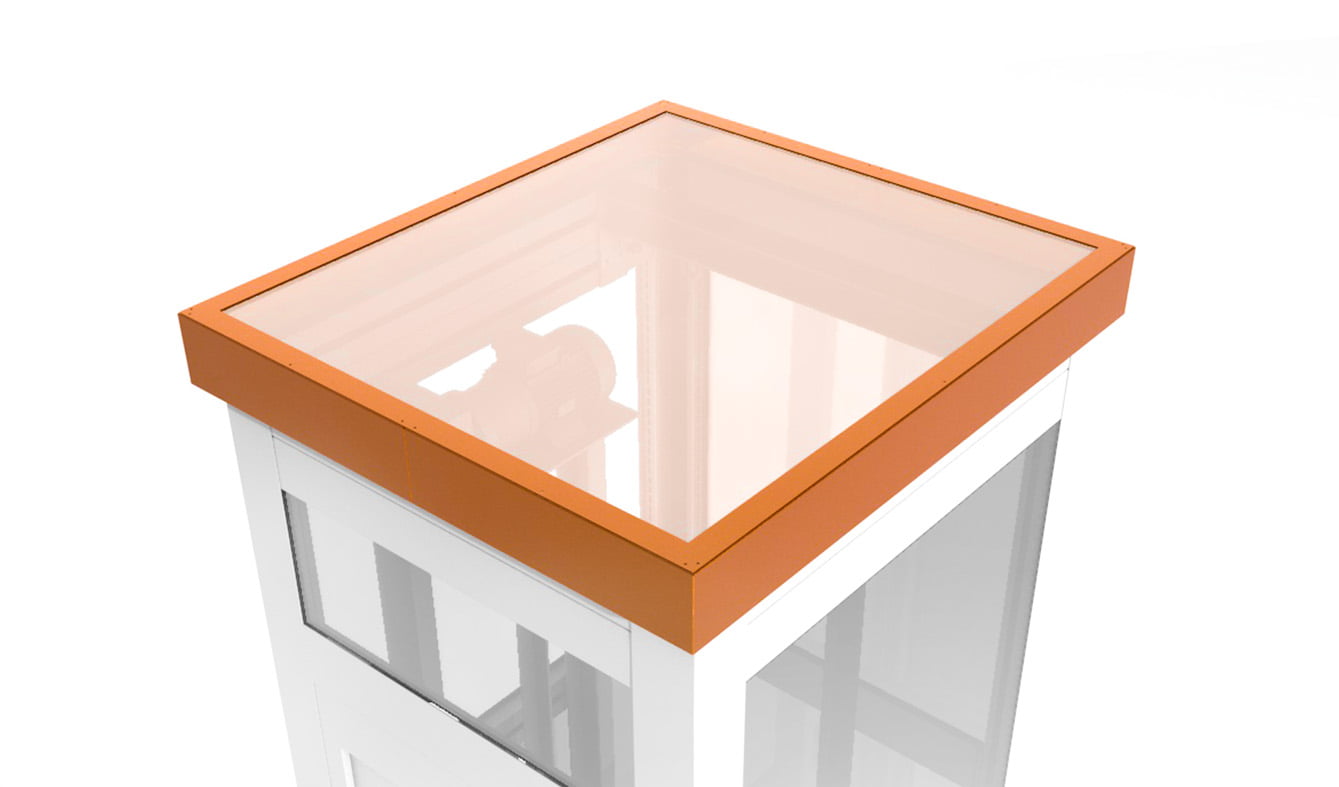

Roof for indoor or outdoor installation. Made in 2 parts, with drip-saving profile.

- 8

Stabilization frame with cross. Also made in 2 parts for easy shipping and installation.

- 9

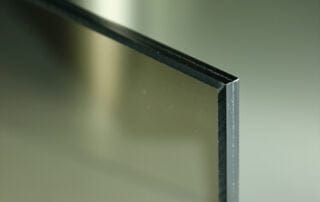

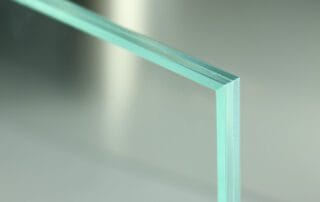

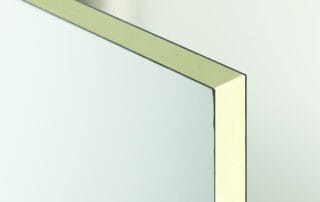

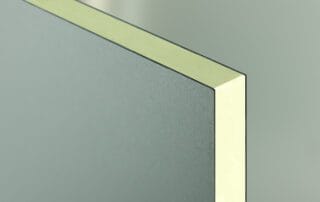

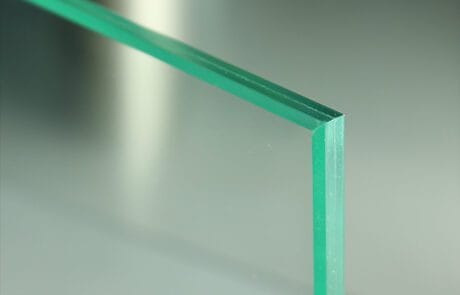

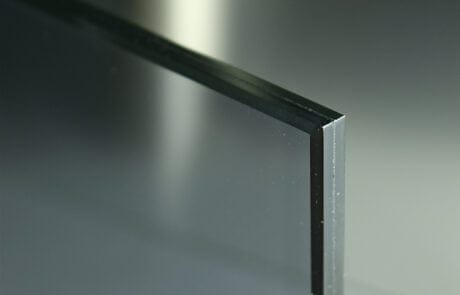

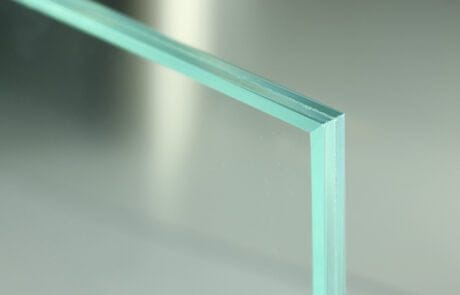

Glass infill or sandwich panel. Installable from inside, also interchangeable during installation.

- 10

Generic horizontal profile. Repositionable during installation.

- 11

Horizontal profile with provision for fixing floor doors. Repositionable and adjustable during installation.

- 12

Door side compensator profile. Made to size and adjustable during installation.

FINISHES AND ACCESSORIES

Glass and sandwich panels

Coating and painting

Accessories

SUPPLY DETAILS

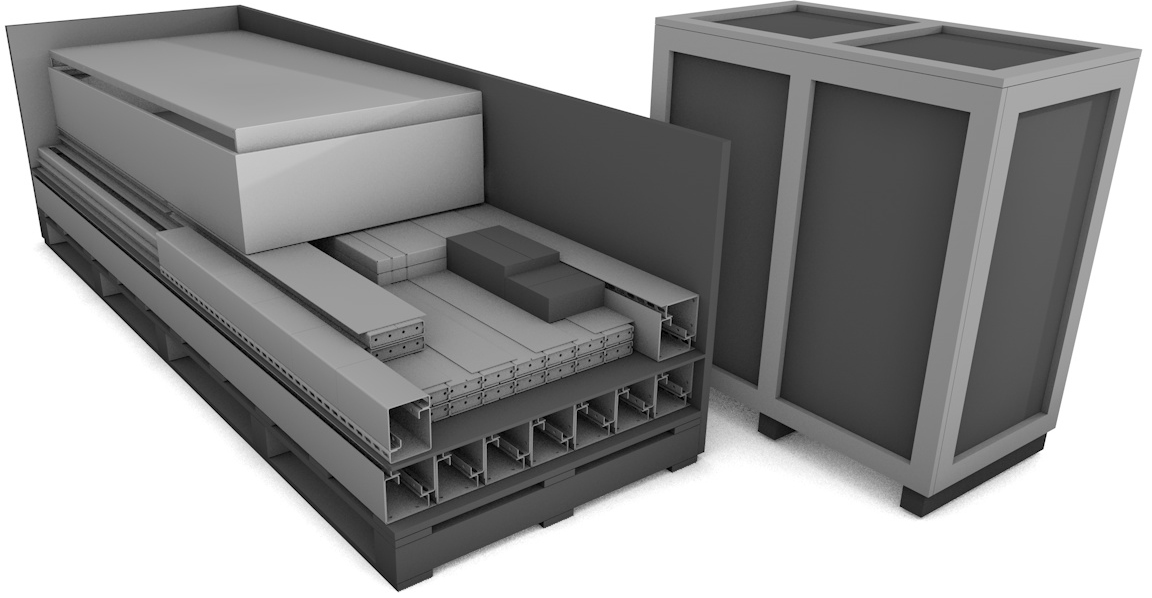

The structure is supplied in a custom-made kit ready for installation on site by bolting and connecting to the host building. It is shipped in a sturdy wooden crate, suitable for shipping, and includes the following items:

- Frame components: All structural and connecting elements, complete with paint.

- Accessories: All required accessories, made to measure.

- Infill: Glazed or blind infill.

- Assembly kit: Galvanized steel screws and bolts, and accessories needed for complete assembly.

- Technical drawings: Detailed technical drawings.

- Manuals: Detailed documentation for installation and use.

- Calculation report: Dedicated calculation report in accordance with Eurocode 3 (UNI EN 1993-1-1:2005).

- CE Marking: Marking according to UNI EN 1090-2:2018.

The structure is available with or without buffering. Alternatively, the technical specifications and dimensions of the planned infills are provided. Excluded from supply are dowels or chemical anchor for connection to the building, and silicones.