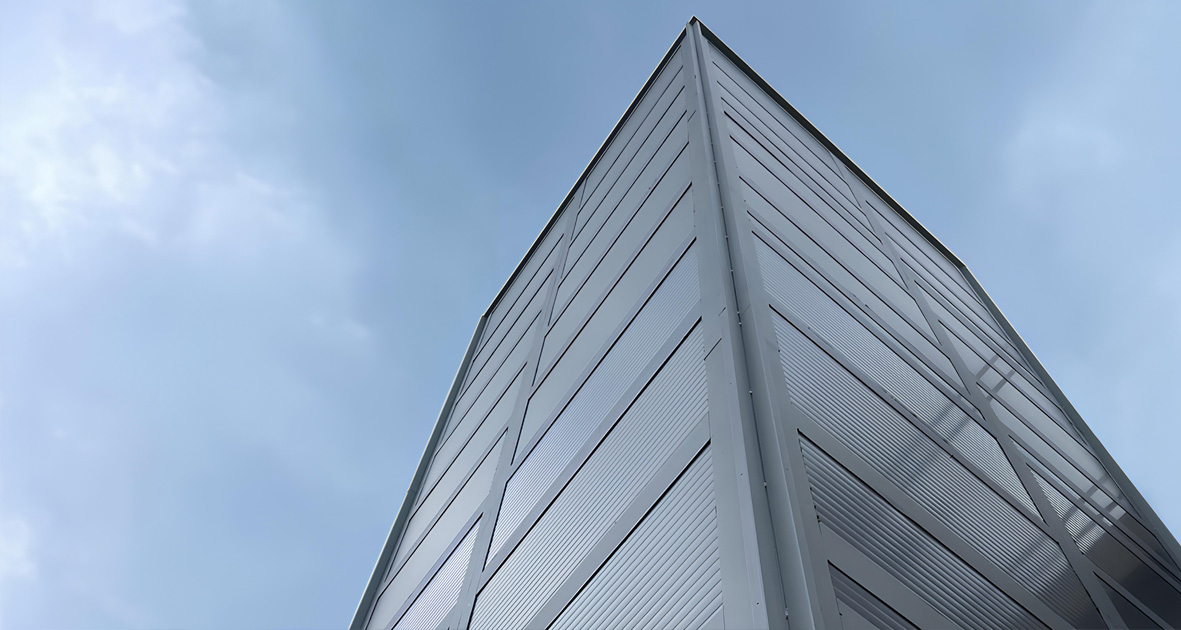

Corten Steel Elevator Shaft

project classic in special execution

Corten Steel Elevator Shaft

Installation Location: Sassari

Status: Completed

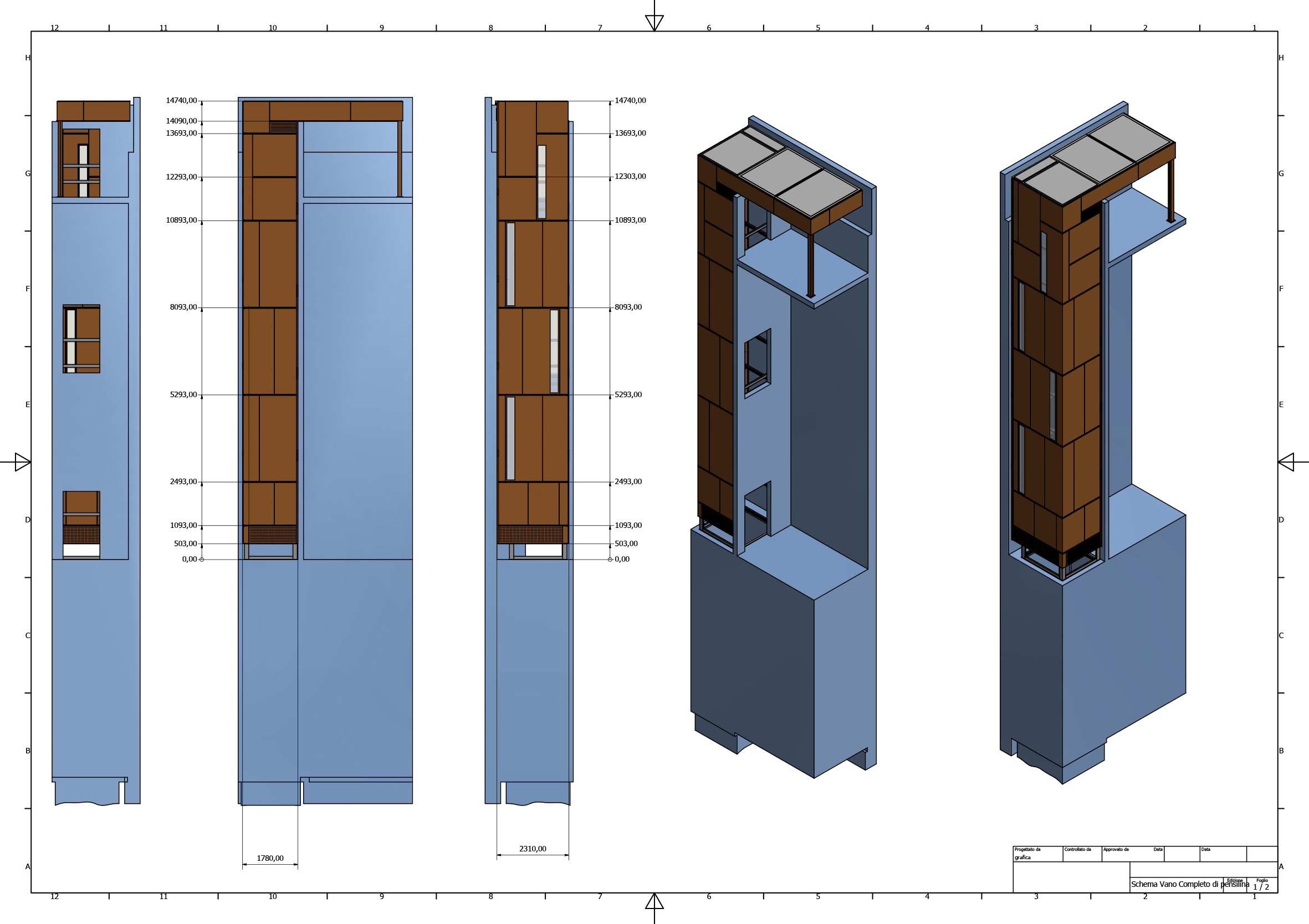

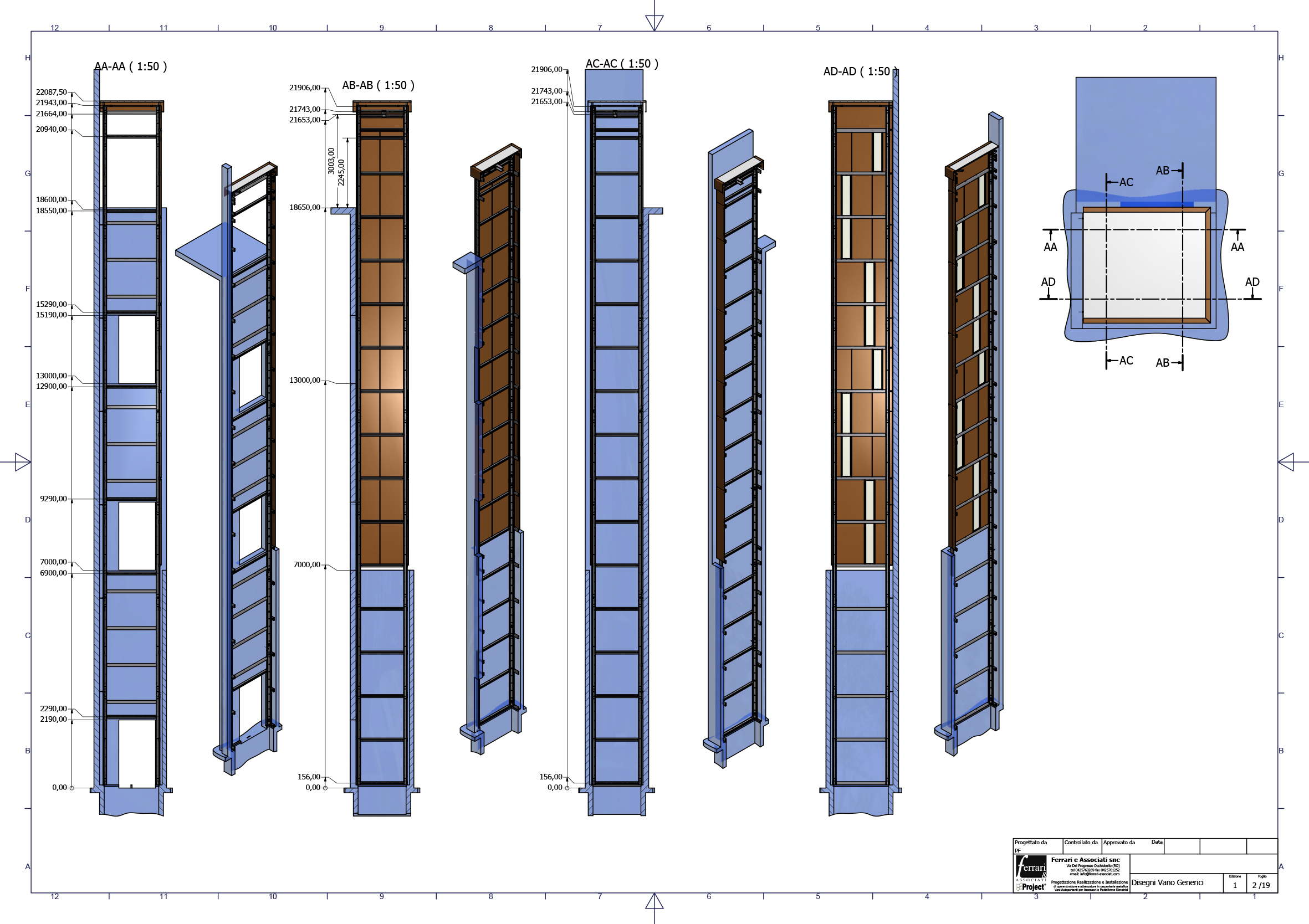

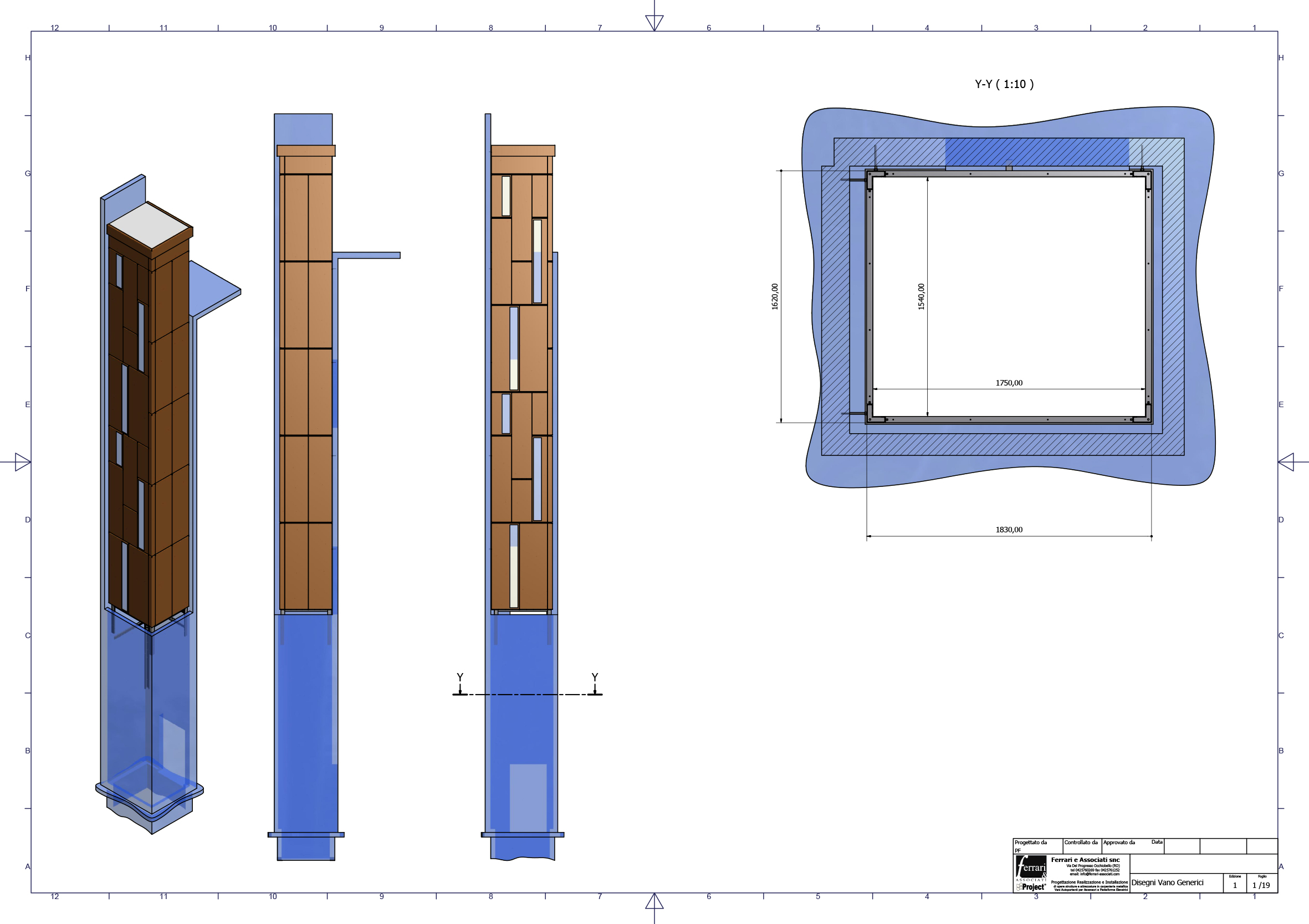

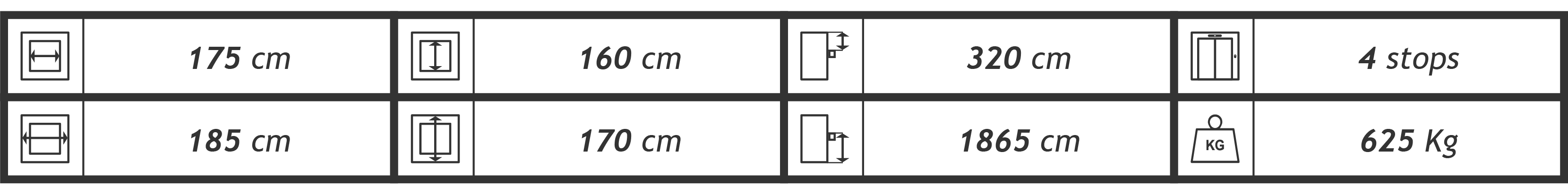

Product: Project Classic in special execution

In the city of Sassari, near the main square, we built, under the direction of a renowned architectural firm, a special elevator made of corten steel and semi-transparent white glass, as well as the plugging of another elevator also made of corten steel. The goal was to integrate harmoniously with the historic host building.

We used the frame of a PROJECT CLASSIC structure, infilled with galvanized sheet metal to ensure watertightness, and applied corten steel and white glass overprinting. For the upper landing area, we also integrated a weather-protected area buffered with clear glass. All materials were machined with numerically controlled machines and installed before rust reached an advanced stage. The proximity to the sea promoted rapid and uniform curing of the rust patina.

The result, both functional and aesthetic, achieved excellent integration with the surrounding environment.