About Us

Founded in 1998, FERRARI E ASSOCIATI was born from the union of experience in the design, fabrication and installation of metal structures. Since its establishment, the company has been introducing and developing products specifically for the elevator industry.

Thanks to state-of-the-art design and production systems, we have created and continuously developed products dedicated to different applications, achieving a complete range that can meet all market needs.

With more than 25 years of experience, we are able to offer widely proven products, handling complex projects with great attention to quality, innovation and reliability.

DESIGN

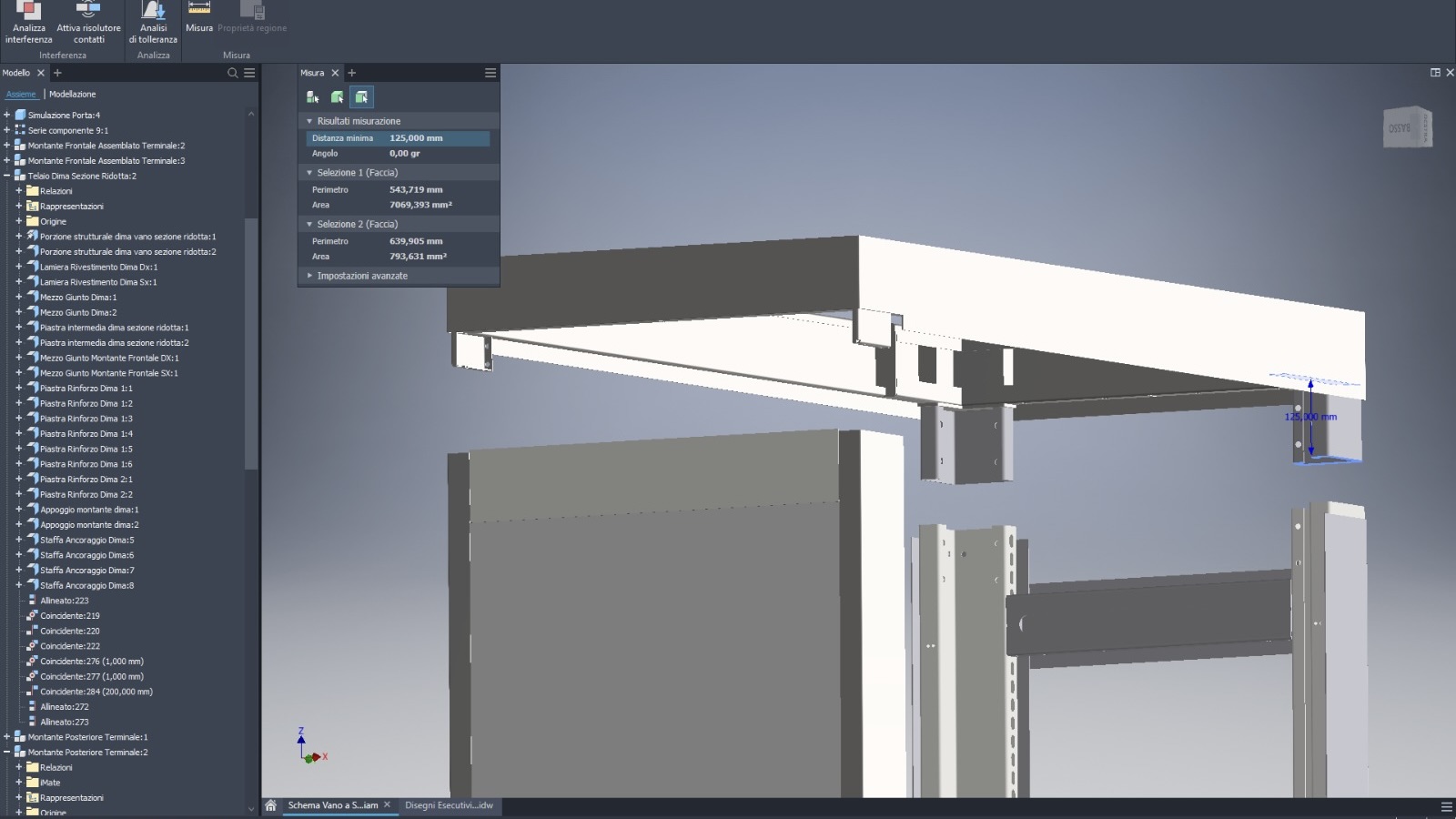

Our custom design system is based on the collection of initial data entered into special spreadsheets, which form the basis of the model of the elevator shaft involved. Development is done through a 3D modeler, using preset parameters that organize all arrangements, including drilling and other necessary machining. After this basic setup, the technician intervenes, who introduces any additions or changes necessary to complete the drawing according to the required specifications.

At this point, components in interchange format are extracted from the 3D model to be transferred directly to CNC machines, which perform machining on the components. This system eliminates any intermediate intervention between the design model and production, thus ensuring a high level of quality.

MACHINING AND FINISHING

Our workshop, after rigorous preliminary dimensional inspections, assembles the components by welding. This process uses specific positioning masks and is based on the technical reference drawings to ensure accuracy and design compliance. After assembly, each component undergoes an additional round of testing to ensure that it meets dimensional tolerances and quality specifications.

Once the components pass inspection, they are sent to surface treatment processes, which may include Cataphoresis or powder coating. The choice of surface treatment depends on the specific requirements of the end product and the expected operating conditions.

This methodical and detailed approach ensures that each component meets the highest quality standards while ensuring the durability and reliability of the final product.

INSTALLATION

Our specialized and experienced team ensures precise installation in accordance with specific plans, working closely with construction management and contracted engineers. Installation is carried out with the utmost precision to ensure compliance with project specifications. Our trained and experienced installation teams work efficiently to complete the installation in a timely and accurate manner.

EXHIBITIONS AND FAIRS

Our company regularly attends major industry events on a European level to meet with our customers and establish new relationships with other companies in the industry. On these occasions, trade shows provide a unique opportunity to present our product developments, provide important updates, and introduce the latest innovations. This commitment enables us to stay ahead of the curve and respond promptly to the needs of the market and our customers.