High capacity hoist compartment

pROJECT WORK in special execution

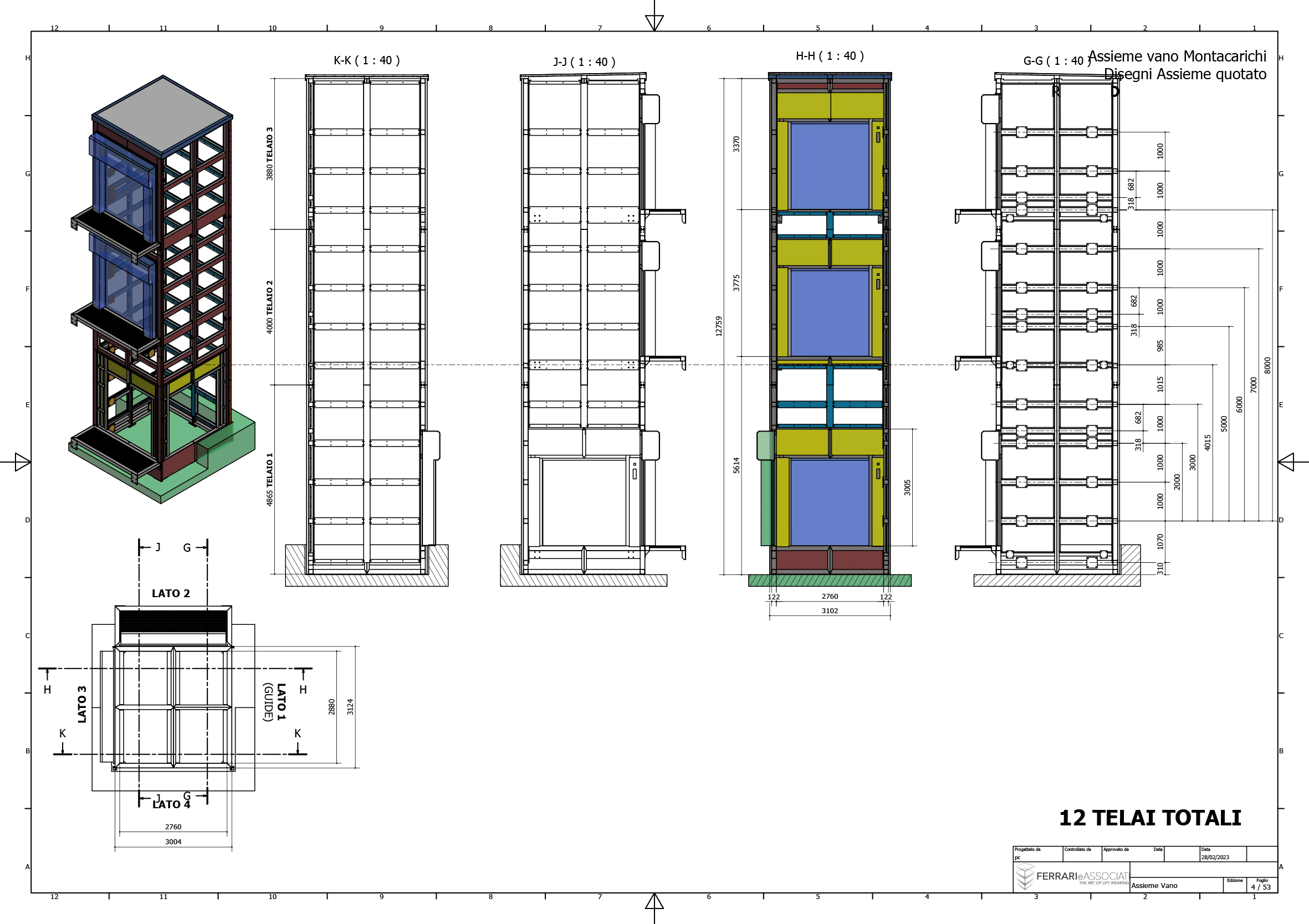

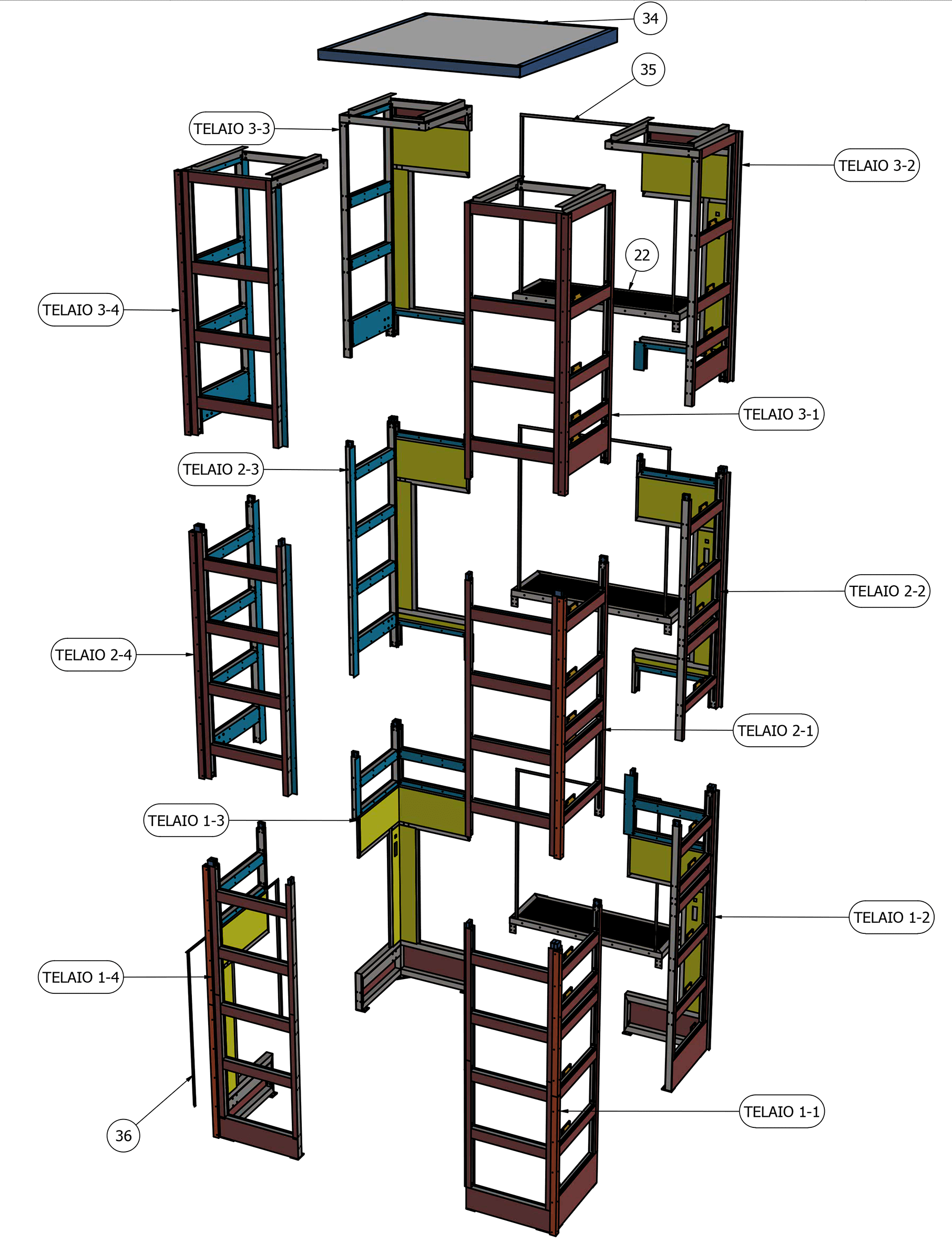

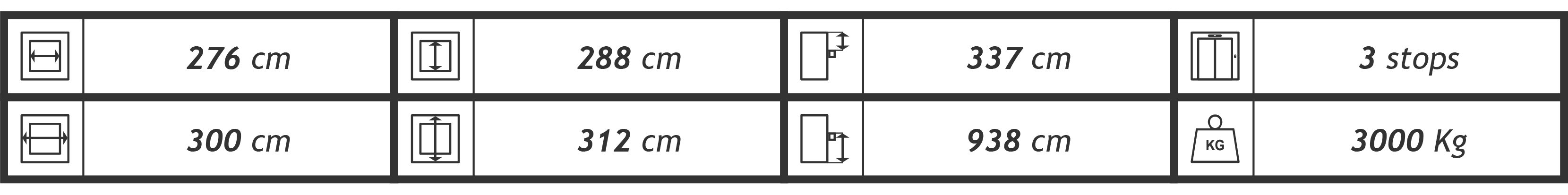

Shaft for High-Capacity Freight Elevator

Installation Location: Genoa Province

Status: Completed

Product: Project Work in Special Execution

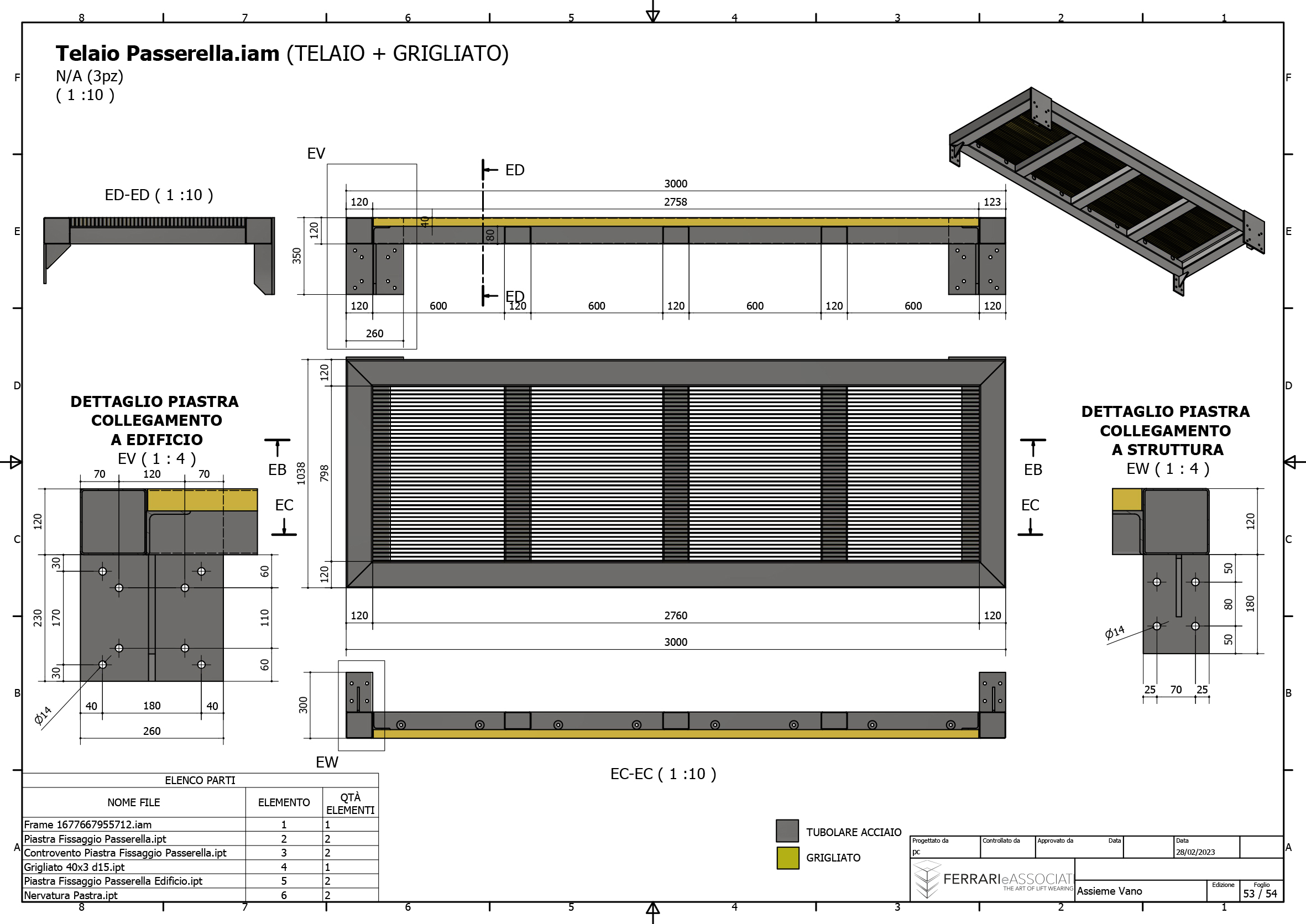

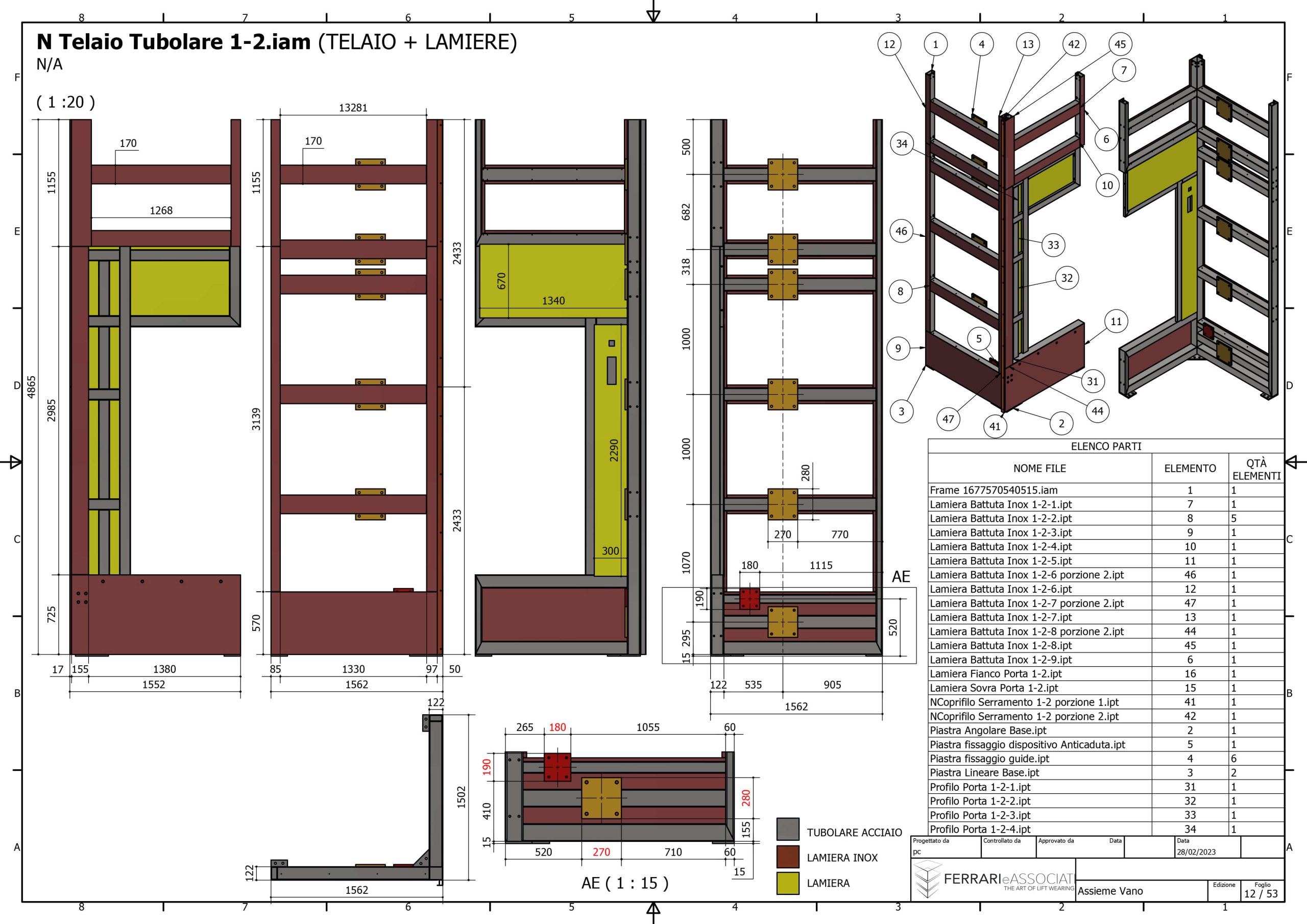

In a company located in the province of Genoa, which needed to transfer forklifts and other heavy loads between floors, we provided a specially designed Project Work hoist compartment. The PROJECT WORK structure was made to ensure a load capacity of 3,000 kg and maintain stability even in the presence of the strong winds characteristic of the area’s coastline.In addition, to ensure the durability of the structure against the salinity in the air, the entire exterior was made of stainless steel and subsequently treated with cataphoresis and powder coating. The structure has also been supplemented with the inclusion of landing gangways having grating panel tops, suitable for supporting large concentrated loads.

The entire inside of the structure features smooth wire, thus ensuring maximum safety for operators. These solutions enabled the company’s needs to be fully met by providing an efficient and durable system for transferring heavy loads between floors.